PROJECT PROFILE FEATURES

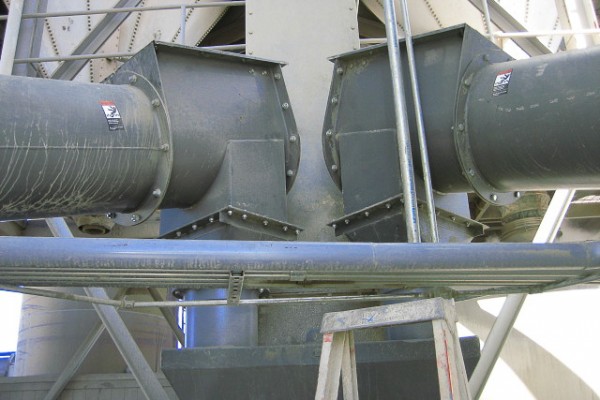

Cement/Fly Ash bulk storage, blending, and Transloading project. This project was done in two phases. Phase I included the addition of Two (2) new 294 ton Cement/Fly Ash silos to include: Air slide conveyors, flow inducement, controls, and structural/mechanical site work. Phase II included the addition of Two (2) new 624 ton silos, relocating the existing bucket elevator, new 150 TPH rail unloading bucket elevator with airslide conveyor, Silo fill airslide conveyors to existing and new tanks, 100 TPH reclaim and blending system to feed the existing Four (4) tanks with new airslide conveyors. Both Phase I and Phase II were done on a design build system basis to include: Project management, engineering, equipment, controls/MCC, structural/mechanical installation with construction management.